by Alexander Simafranca

With growing consumer awareness to the environmental dangers of single-use packaging, there is a widening variety of product packaging making it onto the shelves. And with more products claiming to be sustainably packaged, how are we as consumers to tell which claims are true and which sustainable products are all hype? One way is to use a helpful metric from the world of sustainable life cycle analysis – embodied energy.

What is embodied energy?

The embodied energy of a material represents all the energy spent to produce the material in a single metric. This includes all of the processing necessary to take it from a raw material to its final form ready for product manufacturing. As such, it is a useful metric in defining the relative energy intensity of one packaging material versus another. Let’s consider a case study to see how this metric can be used to compare different types of drink packaging available today.

Case Study: Juice Box Anyone?

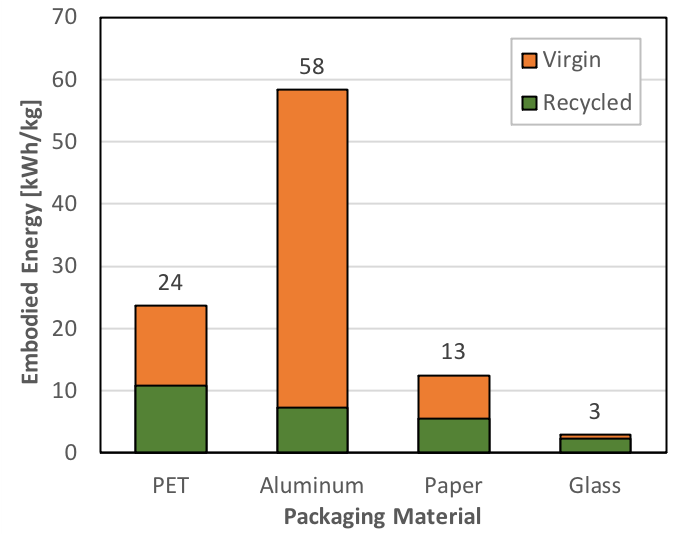

Among the traditional mix of plastic bottles, glass bottles, and aluminum cans, paper cartons are on the rise as an allegedly more sustainable packaging option. Let’s consider whether this claim is true. Plotted in Fig. 1 below are the embodied energies [1] of each packaging material as well as the embodied energies of the recycled materials per unit weight.

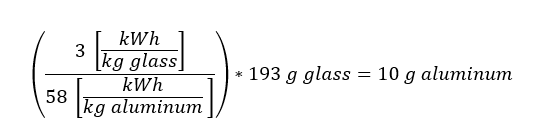

From this data, it is clear that for packaging of equal weight the best choice of packaging material is glass. But different types of packaging typically don’t weigh the same, so how do we adjust for this? A simple estimation method is to take the lowest embodied energy value and divide it by that of a target material, then multiply by the weight of the lowest embodied energy material. For example, comparing a 12 fl oz glass bottle weighing 193 grams [2] to an aluminum can we get meaning that an aluminum can must weigh less than 10 grams to be less energy intensive than a glass bottle. An aluminum can typically weighs about 14.9 g [3], which misses the mark from the point of embodied energy (more on this in a second). Quick calculation yields that a polyethylene terephthalate (PET) bottle must weigh less than 24 g and a paper carton less than 45 g to beat the glass bottle. With the typical PET bottle weighing in at 10 g [4] and a paper carton around the same, the most sustainable packaging options based on virgin material values are paper cartons and PET bottles. So paper drink cartons indeed pass muster as a sustainable packaging option.

The Greater Picture

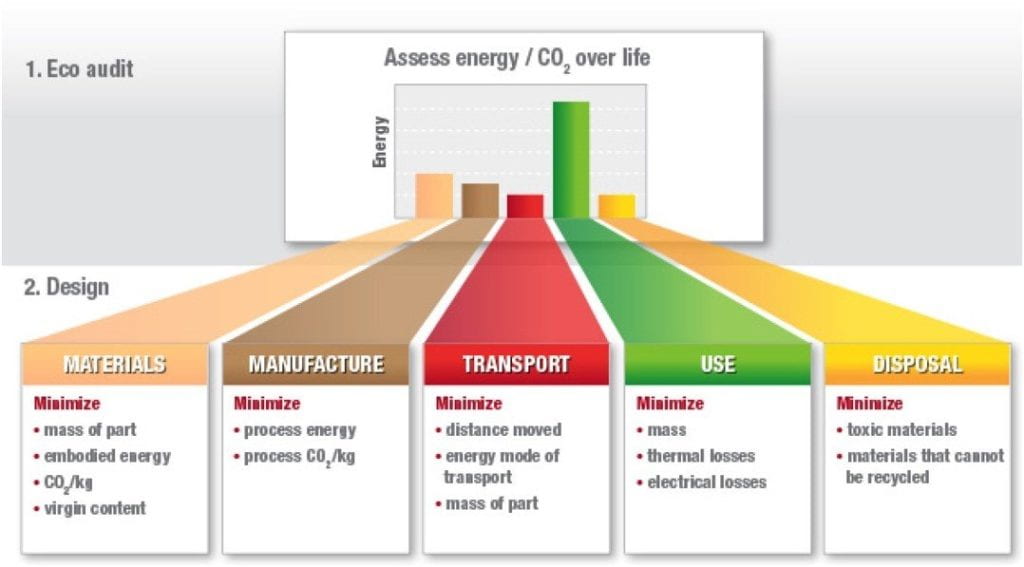

When considering which packaging material to use, we must consider the full lifetime of the packaging, from material creation to disposal (Fig. 2) [5]. Embodied energy tells us about the energy consumed in the birth of a material. After a material is made, it is then manufactured into goods, transported to a seller, used by a consumer, then finally disposed either by recycling or into a landfill. In Fig. 1 above, the embodied energies of the packaging materials when recycled from used packaging rather than from raw materials are plotted in green. Using the same estimation method as previously explained with these recycled values, we see that an aluminum can must weigh less than 62 g, a PET bottle less than 41 g, and a paper carton less than 79 g to be less energy intensive than a glass bottle, all targets easily met by current packaging. Recycling considered, glass is the most energy intensive packaging option and aluminum and paper packaging rise to the top as most sustainable. When recycling rates are high, the embodied energy of the recycled material better represents the energy it takes to manufacture new packaging and more materials become sustainable packaging options. That’s the power of recycling.

We have defined here embodied energy as a metric for estimating the energy intensity of drink packaging and have demonstrated its use in comparing new paper carton drink packaging with traditional plastic, glass, and aluminum options. The calculus of environmental stability is ever changing as new technologies are developed and as inefficiencies are removed from manufacturing and recycling systems. This method for estimating the energy intensity of materials will hopefully provide a foundation from which you may navigate your sustainable product choices in the future.

References

- Ashby, M. F. Materials and the Environment. Elsevier Science (2012).

- 12 oz. (355 ml) amber glass long neck beer bottle, twist-off crown, 26-502. The Cary Company. https://www.thecarycompany.com/12-oz-amber-glass-long-neck-beer-bottle-crown-twist-off-8025702#specifications (accessed December 10, 2021).

- How many aluminum cans equal to 1 pound? Recycle USA Inc. https://recycleusainc.com/how-many-aluminum-cans-equal-1-pound/ (accessed December 10, 2021).

- Little-Known Facts about PET Plastic. PET Resin Association. http://www.petresin.org/news_didyouknow.asp (accessed December 10, 2021).

- Early-stage materials selection based on embodied energy and carbon footprint. Materials & Design, 178 (2019), 107861.

Alex is part of the 2021-2022 INFEWS program cohort and a PhD student in Chemistry and Biochemistry at UCLA. His research focuses on the doping of amphiphilic semiconducting polymers in aqueous environments and gain insight into new uses towards emerging sustainable power systems such as high-efficiency all-organic flexible solar cells and semiconducting polymer-mediated photoredox catalysts for hydrogen evolution.

The blog is part of the INFEWS Social Media Series and the Field Lab course.