by Renan Valenca

Cheese is one of the oldest foods on earth dating back to 8,000 BC. From all the different types of cheese, the Italian cheese called “Parmigiano Reggiano” – also known as parmesan cheese – is one of the most popular cheeses in the world. The production of Parmigiano Reggiano started in the 12th century in Italy in the cities of Parma and Reggio Emilia – hence its name –, and nearly 15% of all the milk produced in Italy is utilized to produce Parmigiano Reggiano [1]. Parmigiano Reggiano is produced with milk from Vacche Rosse (red cows) that are located in the Parma region, but the cheese is exported and known worldwide due to its sharp flavor and granular texture that comes as a result of the long aging of the cheese and the high-quality products used in the process.

In October 2021, I had the pleasure of touring a local Parmigiano Reggiano industry in Reggio Emilia (Italy) called Consorzio Vacche Rosse. Parmigiano Reggiano has a legal designation called “Denominazione di Origine Protetta” (DOP, Protected Designation of Origin) which is given by the European Union to recognize the authenticity and quality of the product. Thus, to produce Parmigiano Reggiano DOP, the Consorzio Vacche Rosse must follow strict laws that go from the feeding diet of the cows to an intense quality-control process. Not only that but the industry must be located in the Parma region as it must use fresh milk of local red cows. The local industry that I visited is part of the consortium and their regulation provides only grass, hay, and certified no genetically modified organism (GMO) feed to their cattle.

The Vacche Rosse industry produces only 20 cheese wheels per day. This sounds like a small number, but nearly 600 liters of milk are used for each wheel. Overall, the cheese production process can be broken into three stages: coagulation, salting, and aging.

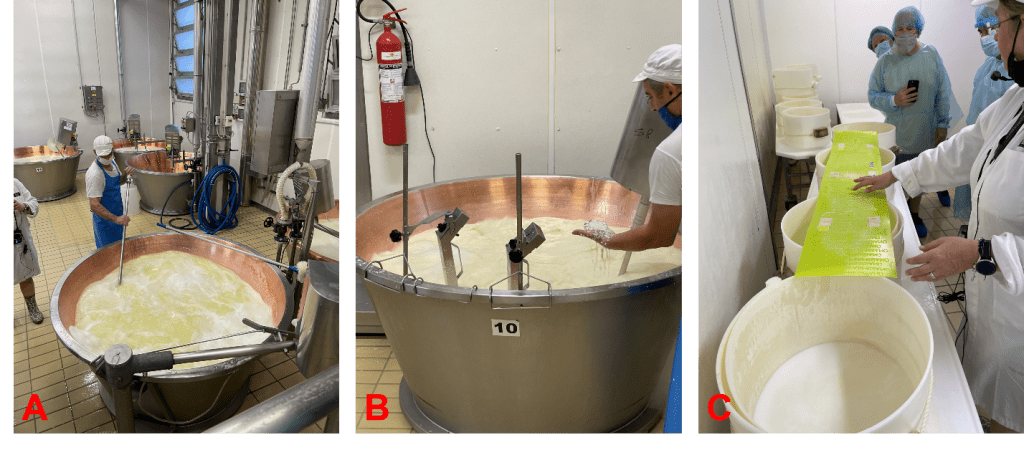

The coagulation process starts with the fresh milk (collected in the morning or the night before) being poured over traditional bell-shaped copper vasts (Figure 1-A). Natural and slow coagulation is used in the process to form the milk by adding rennet from previous batches as a starter. The cheese blocks that are being formed are broken by the master cheesemaker who constantly checks the texture of the cheese (Figure 1-B). After nearly an hour, the granules of cheese settle to the bottom of the tank. Using a cloth, the cheese is removed from the tank and placed in a cheese mold which gives its final form. The name of the factory, the month, and year of production are written inside of the cheese mold (Figure 1-C). Moreover, “Parmigiano Reggiano” is also written along with the initials “DOP” to ensure the authenticity of the cheese.

Figure 1 – Production process of Parmigiano Reggiano at the Consortium Vacche Rosse in Reggio Emilia, Italy. Photo credit: Renan Valenca.

After a few days, the salting process starts by submerging the cheese wheel into a salty solution located in a warm room where salt flows from the solution to the cheese by osmosis (Figure 2-A). The salt used for the solution is called Mediterranean salt and is also produced nearby. The water is saltier than the ocean and more salt is added daily to ensure that the salting process does not stop. Every day an employee must come and turn each wheel to ensure that the exposed wheel area gets underwater. The wheel stays submerged for nearly 25 days before moving to the last process.

In the aging process (Figure 2-B), the cheese wheel is kept in a moisture-controlled room at room temperature for periods that varies from 12 to 36 months – hence the form the industry sells the cheese: 12-, 24- or 36-months old Parmigiano Reggiano. During aging, the cheese creates one of its most unique characteristics: crunchiness. What happens here is that those crunchy parts of the cheese are tyrosine (amino acid) which comes from the main protein of the milk called casein [2]. After the aging, an accredited inspector sent by the European Union comes and inspects the quality of the cheese using a tool that is similar to a hammer. The inspector knocks the cheese using the hammer and listens to the sound – if unwanted air bubbles were formed inside the cheese, that will change the sound of the cheese and the inspector will place the cheese aside. If the cheese does not pass the test, the wheel of cheese is marked with horizontal lines (Figure 2-C) and it cannot be sold as a Parmigiano Reggiano DOP despite being a high-quality product. Those cheeses are instead sold to local restaurants for more affordable prices as they cannot be advertised as Parmigiano Reggiano DOP.

Figure 2 – Salting, aging process, and quality assurance of Parmigiano Reggiano. Photo credit: Renan Valenca.

While eating fresh Parmigiano Reggiano was a great experience that I had in Italy, it blew my mind to think how much methane emission was connected to that process. Every year more than 3.5 million wheels of Parmigiano Reggiano are sold worldwide [3]. This means that more than 2.0 billion liters of milk are used every year to produce Parmigiano Reggiano. Previous studies have shown that red cows produce between 20 to 30 liters of milk per day while also producing nearly 330 grams of methane per day [4]. Thus, to produce 3.5 million wheels of Parmigiano Reggiano, more than 20,000 tons of methane must be emitted into the atmosphere every year. Although more than 80% of the methane emission could be reduced by switching the cattle feed to a seaweed-based diet [5], it is unlikely that the Italian culture would agree with changes that are likely to impact the taste of the Parmigiano Reggiano cheese. Knowing the production of Parmigiano Reggiano started in the 12th century and continues to rise, it is disturbing to know how much this industry is accelerating climate change through the emission of greenhouse gases like methane.

In 2011, two cheese factories located in Parma and Reggio Emilia agreed to invest in solar energy to run their entire industrial process [6] therefore reducing their methane emission. This initiative stimulated other cheese industries in Italy to change their energy matrix. Differently from most production processes in the world that also emit methane, the production of Parmigiano Reggiano utilizes only local supplies. Because freight transportation is a large contributor to gas emission in the world [7], it is fair to say that the production of Parmigiano Reggiano has little to no contribution related to freight transportation of supplies, which shows the importance of local food production in reducing the industry’s footprint. While it may be unlikely that the cattle and feed type will change in the production of Parmigiano Reggiano, other significant actions should be considered and implemented by the cheese industry to reduce their methane emissions.

References:

- http://www.latteriavalle.com/?page_id=55

- Buhler, S., Riciputi, Y., Perretti, G., Caboni, M.F., Dossena, A., Sforza, S. and Tedeschi, T. (2020) Characterization of Defatted Products Obtained from the Parmigiano–Reggiano Manufacturing Chain: Determination of Peptides and Amino Acids Content and Study of the Digestibility and Bioactive Properties. Foods 9(3), 310.

- https://www.parmigianoreggiano.com/it/news/2019-anno-record-per-valore-produzione-e-per-export-parmigiano-reggiano/

- Laubach, J. and Kelliher, F.M. (2004) Measuring methane emission rates of a dairy cow herd by two micrometeorological techniques. Agricultural and Forest Meteorology 125(3), 279-303.

- Roque, B.M., Venegas, M., Kinley, R.D., de Nys, R., Duarte, T.L., Yang, X. and Kebreab, E. (2021) Red seaweed (Asparagopsis taxiformis) supplementation reduces enteric methane by over 80 percent in beef steers. Plos One 16(3), e0247820.

- https://ambiente.regione.emilia-romagna.it/it/notizie/primo-piano/vecchi-primi-piani-plone-4/passaggio-plone-55-pp/parmigiano-reggiano-ambiente

- https://www.epa.gov/smartway/why-freight-matters-supply-chain-sustainability

Renan is part of the 2021-2022 INFEWS program cohort and a PhD candidate in the Department of Civil & Environmental Engineering at UCLA. His research focuses on boosting the resiliency of stormwater biofilters using fungal-based methods to mitigate the impacts of climate change stressors on the quality of surface and subsurface water.

The blog is part of the INFEWS Social Media Series and the Field Lab course.